product

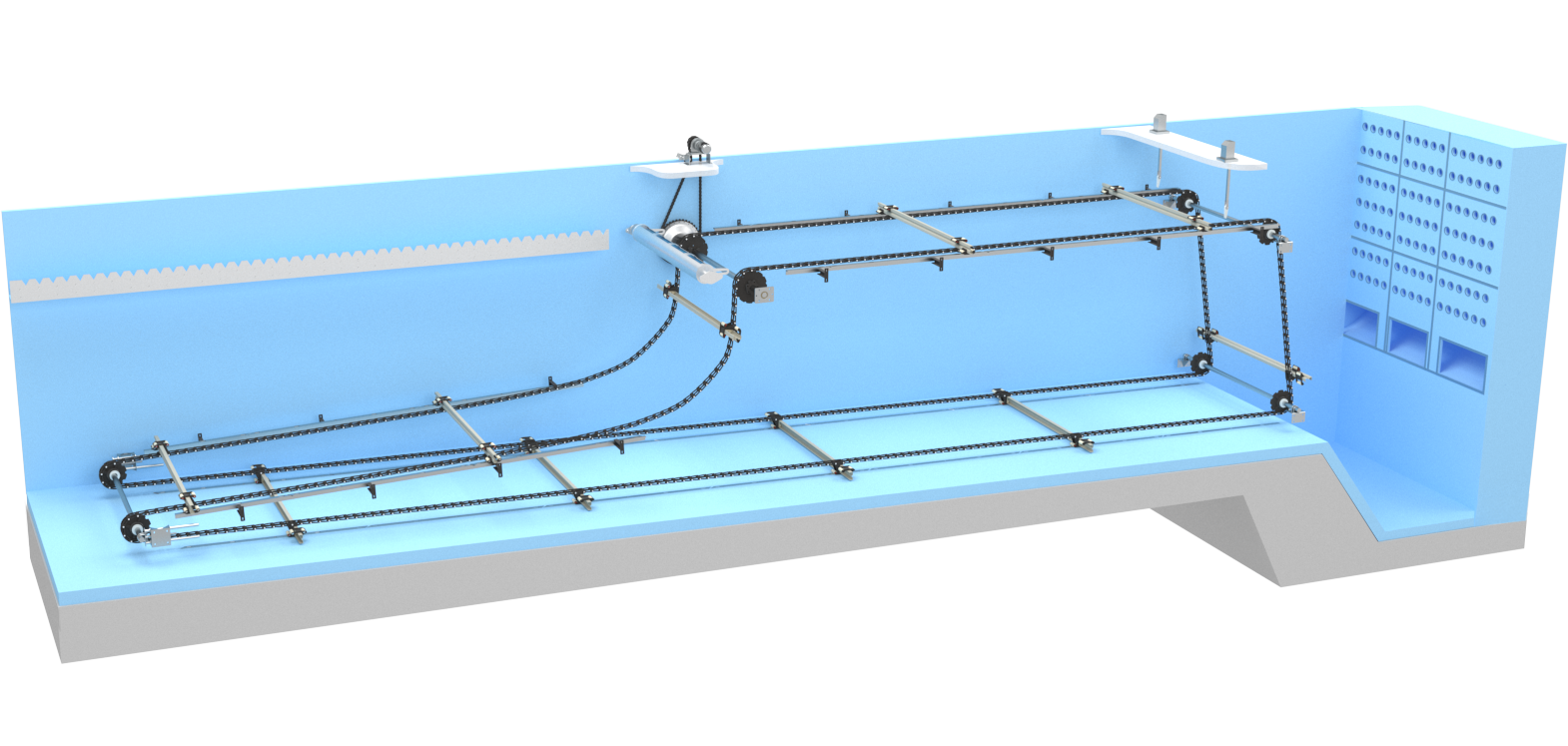

Front Roller Type Sludge Collector

The load in the collector is reduced by more than 50%, so it is possible to operate reasonably by reducing energy consumption and physical/human consumption by reducing power consumption by more than 50%.

Front roller type sludge collector

Driven Sprochkets |

|

|---|---|

|

|

| Function | It is a dish-shaped structure having elasticity in the tension of the dive chain, and transmits the power of the driving unit to the head shaft of the collector. |

| Characteristics | It is a four-division separation structure that allows only the retardation part to be replaced in case of wear, making it easy to repair and repair, and can be selectively applied according to the material quality and characteristics of each site. |

| Configuration | 40NT(or 30NT), PCD 844.6. PITCH 66.27mm(or 78.1mm) |

| quality of the material | Polyurethane (PU), HDPE, STS304+GUR |

Head Sprochkets |

|

|---|---|

|

|

| Function | It is fixed to the head shaft (drive shaft) to drive the collector, and transmits the power transmitted from the DRIVEN chain to the main body chain. |

| Configuration | 12NT, PCD 588.8m PITCH 152.4mm |

| quality of the material | Polyurethane (PU), HDPE. |

Idler Sprochkets |

|

|---|---|

|

|

| Function | Located on the corner shaft, tail shaft, and idler shaft, it is driven by the loop chain in combination with the three-ve bearing and is collectively referred to as an idle sprocket. |

| Configuration | 9NT, PCD 446.6m PITCH 152.4mm |

| quality of the material | Polyurethane (PU), HDPE. |

An apparatus for preventing dropping of a driving chain (Patent No. 10-1648763) |

|

|---|---|

|

|

| Function | By automatically stopping the reducer when the drive chain is broken, it is possible to respond quickly to on-site unexpected events. |

∑ Flight |

|

|---|---|

|

|

| Function | It scraps sludge on the bottom of the immersion battery and has strength and acid resistance above the sludge load. |

| Characteristics | The flyt reinforced the shape of the product to have high strength, and in combination with the front roller, the load of the collector is reduced by 50% or more, proving the excellence of only the considering technology for the slurry collector. |

| quality of the material | NYLON + HDPE |

Auto Centering Weall Bearing (Patent No. 10-1648763) |

|

|---|---|

|

|

| Function | The bearing housing is made of a non-metal for corrosion and chemical resistance in a BALL shape to help the self-alignment of the shaft by fixing the drive shaft to the wall surface of the immersion battery. |

| quality of the material | STS 304 + GUR |

Shaft clamp |

|

|---|---|

|

|

| Function | It protects the axis against risk factors such as rotation of the axis and left/right slip bending, and stable operation is performed. |

| quality of the material | STS 304 |

Wear Strip (Return Strip, Bottom Strip) |

|

|---|---|

|

|

| Function | It is attached to the return track on the top of the immersion battery and to the bottom of the immersion battery to reduce friction, thereby reducing wear and power consumption. |

| Characteristics | The bottom strip is reinforced with 20 tons to cope with surface defects on the bottom of the immersion battery. |

| quality of the material | HDPE |

Take-up device |

|

|---|---|

|

|

| Function | It is a take-up site that controls the sagging, drag, and tension of the roof chain and is easy to maintain with easy tension adjustment. |

| quality of the material | STS |